-

Leave a Message : info@fsjspm.com

-

Phone : +86-13266347573

Leave a Message : info@fsjspm.com

Phone : +86-13266347573

In modern industrial production, automatic packaging equipment has become a key tool to improve production efficiency and reduce labor costs. As an important part of packaging automation, box packing machine (or called cartoning machines) are widely used in food, medicine, daily chemicals, electronics and other industries, and can efficiently complete product cartoning, sealing, coding and other processes.

Basic Working Principle

Box packing machine is an automatic packaging equipment, which is mainly used to load products into paper boxes or plastic boxes, and complete operations such as folding boxes, sealing, etc. Its workflow usually includes the following steps:

Automatic paper boxes feeding: The machine takes flat paper boxes from the storage slot and unfolds them into a state to be loaded.

Product transportation and positioning: The products are accurately fed into the box through a conveyor belt or a manipulator.

Cartoning and sealing: The machine automatically folds the lid and seals, and some models also perform hot melt glue sealing or tongue lock boxes.

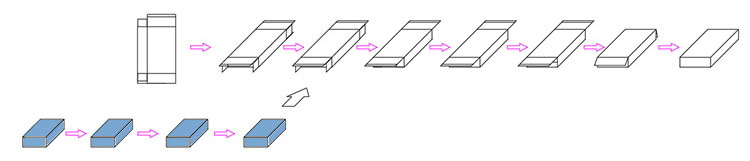

Cartoning Process

Cartoning Process

According to the characteristics of the product, box packing machines can be divided into different types such as vertical box packing machines, horizontal box packing machines, and continuous box packing machines, which are suitable for the packaging needs of products of different shapes and sizes.

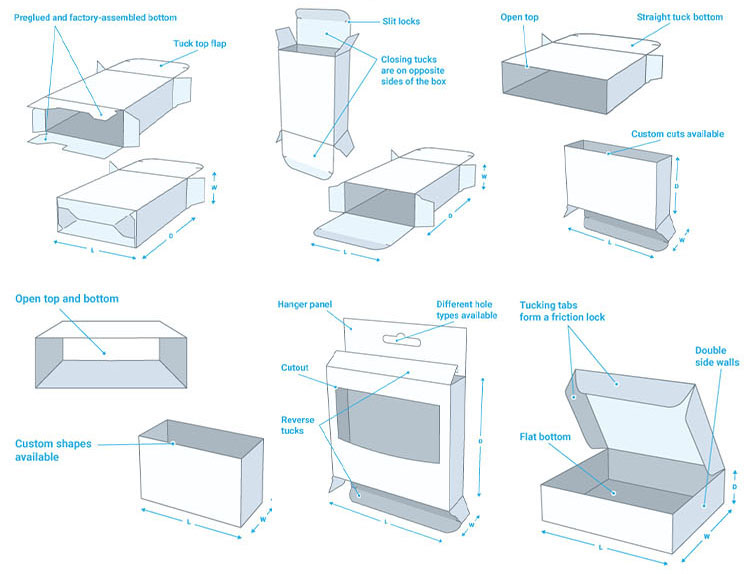

Box Types

How Can Box Packing Machines Improve Production Efficiency?

1. Increase Packaging Speed & Reduce Manual Dependence

Manual packaging is limited by the operating speed of workers, and usually the working speed is only 5-10 boxes per minute, while the packing speed of automatic box packing machine can reach 60-300 boxes/minute (depending on the machine model), and the efficiency is increased several times or even dozens of times. For example, in the pharmaceutical industry, blister plate box packing machines can reach 200 boxes/minute to meet the needs of high-speed production. In the food industry, small products, such as biscuits and chocolates, can be packed in paper boxes at a speed of up to 300 boxes/minute.

Fully automatic box packing machines can operate continuously for 24 hours, unaffected by factors such as worker fatigue and shift changes, ensuring production stability.

2. Reduce Packaging Errors & Improve Product Consistency

Manual packaging is prone to problems such as wrong packaging, missing packaging, and loose sealing. Cartoning machines use photoelectric sensors, visual inspection systems and PLC control to ensure that products are correctly boxed to avoid manual problems. And the box is tightly sealed to avoid box opening during transportation. Labels and instructions can also be placed accurately. This not only reduces rework and scrap rates, but also improves customer satisfaction and reduces the risk of complaints.

3. Reduce Labor Costs & Optimize Production Processes

Traditional packaging lines require a large number of workers to perform operations such as boxing, sealing, and palletizing, while box packaging machines can achieve fully automatic or semi-automatic production, reducing labor demand. A fully automatic cartoning packing line only requires 1-2 people to monitor, while manual packaging may require 5-10 people. In the long run, the machine operating cost is lower than the labor cost, and the return on investment is high. In addition, the cartoning machine can be linked with bottle filling machines, pouch packing machines, labeling machines, case packing machines and other equipment to form a complete automatic packaging line, further improving overall efficiency.

4. Improve Packaging Quality & Enhance Brand Image

Through precise mechanical structure and intelligent control system, the box packing machine can ensure that the corners of each packaging box are flat, the seal is tight, and the appearance is neat, giving the product a high-end and unified visual effect. Stable packaging quality not only reduces the breakage rate during transportation, but also ensures that product information is clear and legible through a precise inkjet system. The machines meet the strict compliance requirements of industries such as medicine and food. This kind of professional packaging presentation can effectively enhance consumers’ recognition of product quality, shape the brand’s professional image, win more consumers’ favor and trust in a fiercely competitive market, and thus enhance the product’s added value and market competitiveness.

Future Development Trends

With the advancement of intelligent manufacturing and Industry 4.0, cartoning machines are developing in a smarter and more efficient direction:

1.AI visual inspection: automatically identify product defects and remove defective products.

2.Internet of Things (IoT) integration: real-time monitoring of equipment operation status and prediction of maintenance needs.

3.Cobot application: cooperate with manipulators to achieve more flexible cartoning solutions.

Conclusion

With the advancement of technology, box packing machines will play a more important role in intelligent manufacturing, helping companies achieve more efficient and flexible packaging production. For companies pursuing high efficiency and high quality, investing in automatic cartoning machines is an important strategy to enhance competitiveness.

If you're looking for a cost-effective and reliable box packing machine solution, feel free to contact Jason Machinery. We’re here to help you automate your success.